- Industries

- Support

- Services

- About

- Brands

- Knowledge Hub

-

-

Case Studies

-

-

- BUY NOW

- Industries

- Support

- Services

- About

- Brands

- Knowledge Hub

-

-

Case Studies

-

-

- BUY NOW

USI is your Power Generation Partner to help you minimize or avoid unscheduled time off the grid. We understand your needs whether your business is coal, nuclear, natural gas, geothermal, wind, solar or hydroelectric. USI provides technical support, training and troubleshooting to help your team of maintenance personal, operational staff, or preferred contractors to Repair, Protect and Upgrade.

We have the expertise and the products to help you repair worn shaft journals, sloppy keyways, splines, leaking pipes, transformers, pump casings and impellers, gate and butterfly valves, duct work, hoppers, hydro turbines, penstocks, boiler skirts, bottom ash hoppers, slurry pumps, coal chutes, pipe elbows, conveyor belts, FDG’s , baghouse, heat exchangers, chillers and water boxes.

USI offers a full line of composite repair and protective coating systems.

Let us help you repair, protect, and upgrade your structures, facilities, and machinery.

We understand the many challenges for Wind Energy by keeping your equipment and machinery up and working while avoiding constantly rising replacement cost. Avoid hazardous “hot work” by using simple to use cold weld alternative.

The degradation of wind towers and blades due to various and often extreme environmental conditions, both at sea and on land, is to be expected. Without adequate protection, this erosion and corrosion can diminish the structure’s durability, dependability, lifespan, and ultimately its economic worth.

USI understands that the solution to these issues lies in selecting and using 100% solids, zero VOC, solvent-free polymeric materials. These products are not only safe for the person applying them and harmless to the environment but also considerably more effective than traditional solvent-based and polyurethane coatings. Duromar has developed an advanced hybrid epoxy coating system, tailored specifically for the protection of both onshore and offshore wind installations. This system delivers exceptional long-term color stability, weather resistance, adherence, and impact resilience.

VpCI corrosion inhibitor emitters from Cortec are also a must when working with electrical panels in corrosive environments. They are as easy to use as they are necessary to protect your electrical equipment, simply get the right size for your contained area and place the emitter into the panel or transformer.

Our experienced team is here to help you tackle all the challenges that come with harnessing Wind Power, with expert technical support, troubleshooting and training.

We understand the challenges of maintaining hydroelectric power equipment while managing replacement costs. Avoid hazardous “hot work” by using cold-weld solutions you can repair instead of replace equipment saving downtime and the cost of replacement.

Hydroelectric plants face erosion and corrosion due to constant exposure to water and environmental conditions. Without proper protection, this damage can shorten equipment lifespan and affect efficiency such as turbines, generators, gates, tanks, and control units. USI, provides 100% solids, zero VOC, solvent-free polymeric materials to protect and repair these critical components.

VpCI corrosion inhibitors also safeguard electrical panels in moist environments. Our team offers expert support, training, and troubleshooting to ensure your hydroelectric operations remain smooth and efficient.

We understand the unique challenges of maintaining solar power installations while minimizing costs. Avoid hazardous hot work by opting for easy-to-use cold weld solutions.

Solar panel arrays and mounting structures are constantly exposed to extreme weather, leading to corrosion and erosion. Without proper protection, these elements can reduce system performance and lifespan. USI provides 100% solids, zero VOC, solvent-free polymeric materials, ideal for maintaining the durability of solar infrastructure. Our team is here to provide expert support, ensuring your solar equipment operates efficiently for years to come.

We understand the critical challenges in maintaining nuclear power equipment while keeping costs under control. Avoid hazardous “hot work” with cold weld solutions that help ensure safety and efficiency.

Corrosion and erosion in nuclear power plants can compromise safety and operations. That’s why USI offers 100% solids, zero VOC, solvent-free polymeric materials. These advanced coatings are safe for the environment, deliver superior performance, and extend the life of your equipment. Our solutions are tailored to meet the rigorous demands of nuclear facilities.

USI carries Resimac, USI Repair Kits, Duromar, Cortec and so much more.

USI carries liquid epoxy coatings, hot/cold applied tapes, wax tapes, rockshield and so much more.

Trending news, industry challenges, and the most recent information on how to repair, protect and upgrade.

In 2024, OSHA is pushing ever harder to reduce the number of injuries and fatal accidents contributed directly to welding, and has labeled such a “high priority” in its operations.

In August 2022, the U.S. Pipeline and Hazardous Materials Safety Administration (PHMSA) (Washington, DC, USA) issued a Final Rule regarding the safety of gas transmission pipelines. These new requirements amend

In August 2022, the Pipeline and Hazardous Materials Safety Administration (PHMSA) issued a Final Rule regarding the safety of gas transmission pipelines. These new requirements amend 49 CFR 192 and

The Oil & Gas industry has been using metallic materials for many years, but in some instances non-metallic materials like thermoplastic polymers and composites can offer a better solution. Ever-increasing

Partnering with USI helps clients like you complete successful projects.

Ready for Winter? 5 Actions You Can Take Today to Prepare As winter approaches, as a maintenance manager or facility owner preparing your infrastructure to handle the challenges of the cold season is crucial. Here are five essential actions you can take to ensure your operations run smoothly and safely:

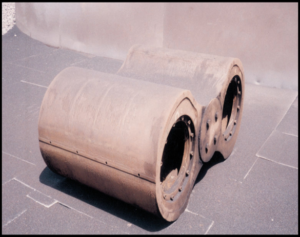

The Problem The twin lobe, of which there are two in each Blower, weighs 3½ tons. As can be seen, it had been subjected to heavy erosion and corrosion as well as abrasion as a result of the very aggressive operating conditions. This sustained attack was altering the profile of

The Problem A significant wind tower was suffering from severe corrosion due to prolonged exposure to harsh environmental conditions, it needed Wind Tower Corrosion Repair. The damage over time necessitated a comprehensive refurbishment to restore the tower’s integrity and performance. The client, seeking a high-performance, long-term repair solution, turned to

The Problem A Chiller Plant needed repair at a Big 10 University after experiencing galvanic corrosion, also know as bimetal corrosion, which was eating away at the metals and causing tubes to plug. This University wanted to lower their energy cost and felt a hydrophobic ceramic enhanced polymer coating would

Everyone can always learn more about “How To…”, what do you need to learn more about?

Learn how to repair, protect and upgrade your chillers with Unconventional Solutions. We review galvanic corrosion and how to repair it on your chiller. Galvanic corrosion (dissimilar-metal corrosion) is an electrochemical process in which one metal corrodes preferentially, when in

This article shows you how to fix an active leak on a concrete pipe in 5 easy steps, without cutting out and replacing a section of pipe. STEP 1 – The pipe was first cleaned and prepped according to the

By Stormy Shaw Flooring Unconventional Solutions offers many kinds of flooring to fit every need. We have both epoxy and urethane coatings for refinishing. We also have repair systems that can increase the life of your existing floor. Whether it

You Asked – We Listened – Hi Temp Coatings We’ve introduced some high-temperature coatings for under insulation corrosion and other hot or aggressive environments you may have. We’ve done thorough research and have partnered with Highland International, who have capabilities