- Industries

- Support

- Services

- About

- Brands

- Knowledge Hub

-

-

Case Studies

-

-

- BUY NOW

- Industries

- Support

- Services

- About

- Brands

- Knowledge Hub

-

-

Case Studies

-

-

- BUY NOW

We understand that in the steel unscheduled down days hurts profitably.

Our easy-to-use pipe repair systems help repair water systems to keep your machinery cool to run at peak operating performance.

If you are in the cold mill and pickling area where use of aggressive chemicals such as HCL (Hydrochloric Acid) can wreak havoc on buildings and structures such as steel supports, roofing, floors, and you your secondary containment areas. (see case studies for our proven track record)

In the Hot Mill area check out concrete solutions that can handle up to 2000F. Concrete repair can eliminate trip slips and falls that cost industry $15 billion annually according to the Liberty Mutual workplace study trips. Trips, Slips and falls account for the 2nd and third most reported injuries.

Being an independent distributor with 10 independent manufacturers, we have customized solutions to fit your needs.

We specialize in safeguarding critical infrastructure through expert consultation and a comprehensive inventory of protective coating products.

Since 2002, our women owned small business has provided solutions for abrasion, erosion, and corrosion control. We are dedicated to providing the highest quality protective coating products, ensuring that your facilities operate at peak efficiency with minimal downtime.

You can trust us to help repair, protect and upgrade your company’s assets effectively, every step of the way.

Whether you are involved in coal mills, precious mineral mining, salt mines, potash mines, copper mines, silver mines or stone quarries, we understand your needs to keep your machinery up and running.

From easy to use metal repair composites to electrometric conveyor belt repair systems, system alternative to AR plates or ceramic tiles we can extend your life of chutes and hoppers.

We also have coatings and innovative VpCI products that can protect mining trucks, hydraulic excavators, dozers, electric rope shovels, rotary drills, rock drills, loaders, draglines, and tractor scrapers from the harsh abrasive and chemical environments involved with mining operations.

We understand that in the stainless steel industry unscheduled down days hurts profitably.

Our easy-to-use pipe repair systems help repair water systems to keep your machinery cool to run at peak operating performance.

If you are in the cold mill and pickling area where use of aggressive chemicals such as hydrochloric Acid, phosphoric acid and boric acid can wreak havoc on buildings and structures such as steel supports, roofing, floors, and you your secondary containment areas. (see case studies for our proven track record)

In the Hot Mill area check out concrete solutions that can handle up to 2000F. Concrete repair can eliminate trip slips and falls that cost industry $15 billion annually according to the Liberty Mutual workplace study trips. Trips, Slips and falls account for the 2nd and third most reported injuries.

Being an independent distributor with 10 independent manufacturers, we have customized solutions to fit your needs.

We understand that in the aluminum industry unscheduled down days hurts profitably.

Our easy-to-use pipe repair systems help repair water systems to keep your machinery cool to run at peak operating performance.

If you are in the cold mill and pickling area where use of aggressive chemicals such as phosphoric acid can wreak havoc on buildings and structures such as steel supports, roofing, floors, and you your secondary containment areas. (see case studies for our proven track record)

In the Hot Mill area check out concrete solutions that can handle up to 2000F. Concrete repair can eliminate trip slips and falls that cost industry $15 billion annually according to the Liberty Mutual workplace study trips. Trips, Slips and falls account for the 2nd and third most reported injuries.

Being an independent distributor with 10 independent manufacturers, we have customized solutions to fit your needs.

Quarries face heavy wear and tear on essential equipment like crushers, conveyors, and screens. Unconventional Solutions provides cold weld alternatives that help repair machinery, such as cracked casings, worn shafts, and leaking pipes, without “hotwork”.

We also offer protective coatings and linings to safeguard critical components like hoppers, chutes, and pumps from abrasion and corrosion, ensuring extended equipment life. In addition, VpCI (Vapor phase Corrosion Inhibitors) technology helps protect electrical equipment from harsh environments, ensuring reliable performance and reducing downtime.

USI carries Resimac, USI Repair Kits, Duromar, Cortec and so much more.

USI carries liquid epoxy coatings, hot/cold applied tapes, wax tapes, rockshield and so much more.

Trending news, industry challenges, and the most recent information on how to repair, protect and upgrade.

In 2024, OSHA is pushing ever harder to reduce the number of injuries and fatal accidents contributed directly to welding, and has labeled such a “high priority” in its operations.

Partnering with USI helps clients like you complete successful projects.

The Problem USI was approached for a heavy-duty floor protection system suitable for the concrete floors operating in an aggressive industrial environment. The ideal system would offer longevity in service as well as an aesthetically pleasing finish. They required a high-performance coating that could also be supplied in a range

The Problem A bridge at a large steel mill was experiencing severe corrosion they needed corrosion protection for their steel bridge. The traditional method of grit blasting to prepare the surface for new coating was deemed too costly by the company. They sought an effective, water-based solution that would minimize

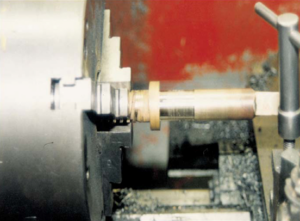

The Problem Valve stem repair: automatic valve stems, such as the one shown in the photograph, had become worn over time due to the aggressive service environment at this fabrication plant. The Company, which manufactures aluminum sheeting and foil, sought a high-performance engineering repair solution, which would result in minimum

The Problem Valve Repair: A Steel Mill was experiencing a leak in one of their coal handling valves. The water was leaking out of the top and they were not able to stop it. They contacted the USI Team for a fast, long-lasting solution so that they could avoid unscheduled

Everyone can always learn more about “How To…”, what do you need to learn more about?

By Stormy Shaw Flooring Unconventional Solutions offers many kinds of flooring to fit every need. We have both epoxy and urethane coatings for refinishing. We also have repair systems that can increase the life of your existing floor. Whether it