By Stormy Shaw

Flooring

Unconventional Solutions offers many kinds of flooring to fit every need. We have both epoxy and urethane coatings for refinishing. We also have repair systems that can increase the life of your existing floor. Whether it be patching, chemical resistance, adding grip or a smooth easy to clean finish USI has you covered!

Refinishing DoorwaysF

Any doorway, especially exterior doorways, can be a victim of corrosion. This can happen from element exposure or even simple wear and tear. We can get your doors closing easy and help provide a more sealed closure to reduce energy costs using our coatings.

Coating Pipes

Coating your pipes, whether it be internally or externally, isa great passive form of corrosion protection. By doing this, you are stopping corrosion before it starts which is a great way to reduce future costs and is very effective for lines that cannot be shut down.

Coating Pipelines

Coating pipelines is not only cost effective but is one of the safest ways to prevent corrosion in industries such as oil and gas. USI offers several different pipeline coating options for both internal and external applications and for different environments. We offer UV protection, underground protection and underwater protection just to name a few.

Pipe Repairs

Pipe repair systems are very beneficial on lines that would not be cost effective to replace. Weather the reason be downtime cost or the inability to shut down, USI has repair systems to fit your needs for these kinds of projects.

Renovating Conveyor Systems

Manufacturing facilities, often, experience wear and tear on their conveyor systems. Rather than replacing a whole conveyor belt, USI has several rubber repair systems for your projects that can get your system looking like new with minimal downtime.

Containment Walls

Weathering on existing containment walls may seem like an uphill battle. Rather than demolishing and rebuilding these walls it is much more reasonable to repair the cracks. These projects will increase the lifespan of the wall.

Chillers

Chillers are an enormous cost for facilities in terms of operation. Walls might need to be knocked down just to replace a chiller in larger buildings. When considering projects on chillers, USI has both the repair systems to fix any existing issues on your chiller and coatings that will increase the lifespan and time between repairs.

Fountain Renovation

Corrosion can corrupt a fountain easily with the constant movement of water. USI rebuild kits can help get the fountain back into working order and our protective coatings can greatly reduce the rate of erosion during your next project.

Acid Pit Lining

Acid pits need acid resistant linings that are regularly maintained. These pits need to be protected because of the heavy chemicals that they are filled with. If you go too long in-between applying these coatings, repairs may be needed for restoration using our rebuild kits.

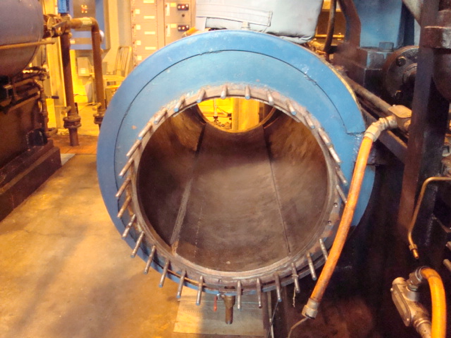

Impeller Coating

We offer a wide range of impeller coatings featuring excellent adhesion, abrasion resistance and compression strength. Corrosion can eat out the volutes and blades in a very short period of time. We also offer metal repair systems to fix any chunks that may already be missing during your project.

Secondary Containment

Secondary containment is a system for containing leaks and spills from any chemical storage tanks or vessels. Coating projects for these instances must be highly chemically resistant as these areas are more prone for chemical spills.

Tank Linings

Tank linings must be used to protect the interior and exterior surfaces from damage. By doing these type of projects, the facility maintains high performance and durability. Often it is much more cost effective to reline a tank rather obtain a permit to replace an existing tank.

Chute Abrasion Repair and Lining

The top seasons for chute repairs are abrasion, erosion and temperature imposed by products. Our repair systems can get chutes back to looking new and our coatings can protect the chute from the need of future repairs. Lining a chute can even protect the product from damage, can prevent possible chemical reactions and these linings can also reduce friction.

Installing Grip Systems

USI offers several grip tapes that will get your company up to safety standard. USI grip systems are imbedded into the flooring for a long-term approach. These projects drastically reduce the number of slips, trips and falls which are OSHA’s number one reported accident.

Shaft Repair

Shafts are often in need of repair due to metal on metal friction. Our metal rebuild system can easily solve this problem. This system creates a metallic bond that can provide a creative and economical solution. These repairs improve wear resistance, reduce downtime, improve machine life and reduce vibration.

These are just a few examples of what our coatings and repair systems can do to help make your projects easier. There are several other solutions too so just give us a call and we can help you today!