HAR & SAR Solutions

HAR and SAR are ceramic putties used for engineering solutions through repair and maintenance. HAR is a more abrasion resistant putty than SAR, which is used primarily in areas requiring more resistance to fine slurries either in liquid or powder form. Common applications are in coal mills, chutes, ash hoppers or deflector plates in FGD systems.

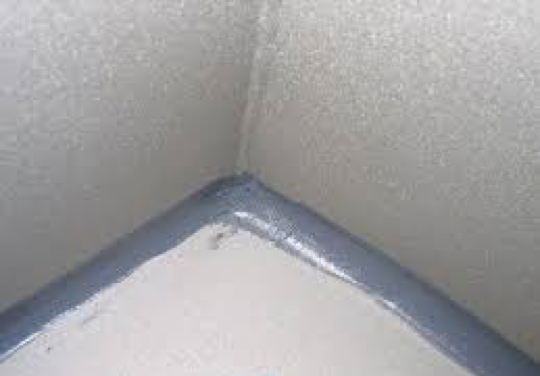

HAR has outstanding resistance to entrained solids and abrasion, has very good chemical resistance, excellent temperature and thermal shock resistance, extended pot life and easily built up for thick applications. HAR is a trowel-on rebuilding compound and can be achieved by multiple layers. It is best applied with a squeegee, trowel or the plastic applicator supplied with the kit.

To apply HAR you press material thoroughly into substrate and insure a completely wetted out surface. HAR may be over coated with other materials such as EAC or EP for enhanced smoothness or increased chemical resistance. Overcoating may begin as soon as the first coat is firm enough to accept a second coat. In high humidity or cold temperatures, a blush may develop which should first be wiped down with clean water.

SAR is a mercaptan cured product designed for coating projects and repairs. It is filled with aluminum oxide and can be built up to an inch in thickness or more. This easy to use putty can be applied to substrates that will be put into immersion almost immediately after application, for both salt and fresh water service. Typical applications are for rebuilding of pump castings, slurry tanks, weld seams or anywhere requiring the restoration of metal components.

SAR returns to immersion service in 90 minutes at 70 degrees F, has excellent abrasion resistance, has a convenient 1:1 mix ratio and may be applied up to thickness of 1 inch or more. It has very good chemical resistance, excellent resistance to entrained solids and abrasion, excellent temperature and thermal shock resistance and extended pot life. SAR is best applied with a squeegee, trowel or the plastic applicator supplied with the kit.

To apply SAR you press material thoroughly into substrate and insure a completely wetted out surface. Build up to the required thickness with a second pass. Large cracks or holes should be bridged with glass or metal cloth. For pinhole control and/or thicker buildup, two or more coats may be employed.