Viscoelastics 101: Revolutionizing Water and Wastewater Treatment

In the complex world of water and wastewater treatment, finding innovative and efficient solutions is crucial for ensuring safety, sustainability, and compliance with environmental standards. Among the various technologies and materials at the disposal of industry professionals, viscoelastic materials stand out due to their unique properties and versatility. As your technical advisors specializing in water and wastewater facilities, we offer an in-depth understanding of how viscoelastic materials can revolutionize treatment processes, along with comprehensive training, troubleshooting, and technical support to maximize their benefits.

Understanding Viscoelastic Materials

Viscoelastic materials exhibit both viscous and elastic characteristics when undergoing deformation. This means they have the ability to both flow like a liquid under sustained pressure and return to their original shape like an elastic solid once the pressure is removed. This dual nature makes viscoelastics particularly useful in a variety of applications, from industrial processes to everyday products.

In the context of water and wastewater treatment, viscoelastic materials are valued for their ability to absorb and dissipate energy, reduce vibrations and noise, and improve the mechanical efficiency of treatment processes. Their unique properties enable them to be used in filtration, sludge processing, and even in the maintenance and protection of equipment.

Applications in Water and Wastewater Fields

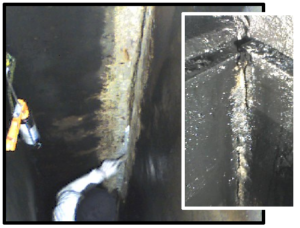

Tank Repair: See how a tank with a large crack in need of repair was fixed within hours instead of days using Viscotaq Viscoelastic Sealant.

Potable Water Pipeline Protection: Contaminated soils can jepordize critical for water pipes. The Viscotaq viscoelastic system can be used to successfully prevent hazardous contaminants from inflitrating these pipelines at gaskets and joints.

Tank Chime Repairs: In this case study USI used viscoelastic sealant and wrap to seal a 1-1/2 inch gap that needed to be filled. Viscotaq products were used to create a seal and long lasting corrosion protection for this tank.

Our Services

Understanding the full potential of viscoelastic materials in water and wastewater treatment requires a deep dive into their properties, applications, and best practices for implementation. That’s where we come in. Our services include:

- Comprehensive Training: Equip your team with the knowledge they need to effectively utilize viscoelastic materials in your treatment processes.

- Troubleshooting: Encounter an issue? I offer expert troubleshooting to quickly resolve any challenges you may face.

- Technical Support: From selection to implementation, receive ongoing technical support to ensure optimal use of viscoelastic materials.

Schedule a consultation today

Are you ready to explore how viscoelastic materials can enhance your water or wastewater treatment processes? To discover the full range of possibilities and to ensure your facility is leveraging the latest innovations in treatment technology, schedule a consultation with me today. Together, we can optimize your operations, reduce costs, and achieve superior treatment outcomes.

Contact USI at 248-735-7000, email cs@usigroups.com or fill out the form below now to schedule your consultation and take the first step towards a more efficient and innovative treatment facility.