The Problem

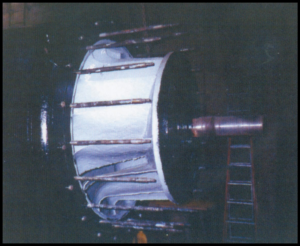

Turbine refurbishment: this turbine was originally built in 1923 and was used in a hydro-electric power plant after decades of service it was showing wear and tear. The client identified that it needed to be repaired and protected so it could provide decades of further service.

The whole turbine was badly worn after years of use without protection. A protective coating was required to protect the equipment from future erosion, corrosion, and cavitation attack.

The Substrate

Metal

The Solution

To start this turbine refurbishment, the turbine was dismantled and all metal surfaces were abrasive blasted to SA 2-1/2.

To start this turbine refurbishment, the turbine was dismantled and all metal surfaces were abrasive blasted to SA 2-1/2.

All blasted surfaces were then coated with RESIMETAL 201 Ceramic Repair Paste which was applied at approximately 1mm this rebuilt some of the metal that had been eroded away from years of service.

Then two coats of RESIMETAL 202 were applied. The first coat was red and was followed by a coat of gray. This system is used so that areas that need preventative maintenance can be easily identified.

The turbine was then reassembled and put back into service.

Products Used

- RESIMETAL 201 Ceramic Repair Paste

- RESIMETAL 202 (2 colors)

For effective turbine refurbishments reach out to the expert team at USI.