The Problem

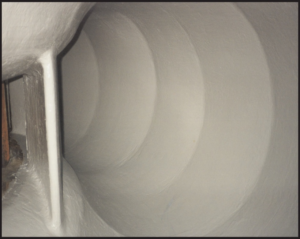

Thousands of liters of water had been continuously pumped through the scroll, which was 120 feet long and had a diameter of 12 feet, to service the requirements of the hydroelectric power station.

The internal surfaces, totaling 1,230 square feet, had deteriorated significantly due to the volume of water and high level of use. It was now in need of complete refurbishment.

The Substrate

Metal

The Solution

A total of 1,118 pounds of RESIMETAL 201 Ceramic Repair Paste were first trowel applied. A stiff bristled angled paint brush was used to smooth out the high spots and uneven areas. A thickness of 750 microns was achieved.

In order to achieve the required finish, the surface of the RESIMETAL 201 Ceramic Repair Paste was sandblasted. After removing the resultant dust, a thin coat of RESIMETAL 209 EIP PU was roller applied over the entire surface.

RESIMETAL 201 Ceramic Repair Paste and RESIMETAL 209 EIP PU are solvent free, polyceramic repair and resurfacing systems, which offer outstanding protection against impingement, entrainment, cavitation, erosion, and corrosion. They are ideal for protecting equipment operating in aggressive environments.