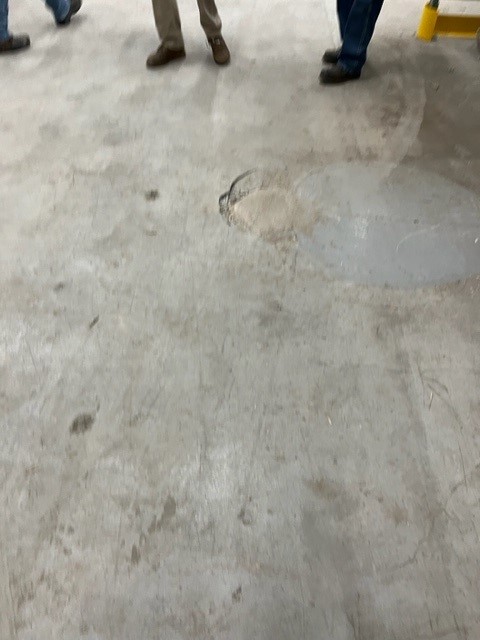

Within a major utility company’s warehouse, there were several places on the building’s floor that had disbanded concrete, and the original coating was fading and failing in spots from years of use.

STAGE 1:

To complete the repair, the staff from Unconventional Solutions, Inc. (USI) was called in. Due to the project’s scale, the project will be finished in two phases. Following the formal evaluation, our crew began by grinding all of the damaged flooring that were already present in the various warehouse. Using a saw, they removed a sizable portion of the disbonded floor, and then they hammered the old flooring all the way down to the concrete substrate. With the use of USI Epoxy Mortar Patch Kits and USI Flexible Broadcast Primer, USI was then able to reconstruct the flooring.

After repairing all damaged areas, USI coated the whole Warehouse floor with two coats of USI Epoxy Slurry (to improve floor flexibility) and all other portions of the shop with one coat. USI After that, USI High Build Epoxy in Grey was applied all over the floor, then aluminum oxide was scattered into the epoxy to provide slip resistance. USI Fast Cure Line Striping was then used to add Yellow Line striping to any areas that needed it.

STAGE 2:

USI will grind the floor for an appropriate anchor profile once the Dock is underway. USI will use Resimac 571 LW to rebuild two bases centered around two columns. USI Flexible Broadcast Primer will be used by USI to prime the entire floor. For a slip-resistant finish, USI will apply a topcoat of USI High Build Epoxy in Grey, Broadcasting aggregate all over.

IN PROGRESS PHOTOS:

AFTER PHOTOS: