THE PROBLEM

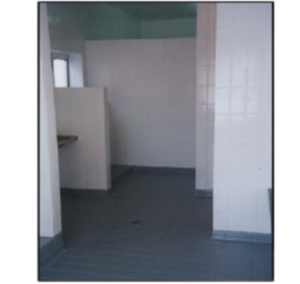

In a local school, the shower cubicles were in a deteriorating state in need of some tile repair, posing health and safety concerns. The tiles on the walls were beginning to detach, and the grout in several areas was failing, leading to bacterial growth. Additionally, the floor tiles and skirting were in such poor condition that water was seeping through the joints, further exacerbating the issue.

THE SUBSTRATE

The shower block primarily consisted of ceramic tiles on the walls and floors, which are commonly used in such facilities due to their durability and ease of cleaning. However, over time, these tiles had succumbed to wear and tear, requiring significant refurbishment.

THE SOLUTION

To address this tile repair, a comprehensive approach was taken:

- Cleaning and Preparation: The walls and floors of the shower cubicles were thoroughly cleaned to remove any dirt, grime, and bacteria. Following this, Sase Grinding was employed to achieve the proper anchor profile, ensuring that new materials could adhere effectively.

- Repair and Patching: Damaged areas were skillfully repaired using the USI Epoxy Mortar Patch Kit. This product is designed for robust and durable repairs, ideal for high-moisture areas like showers.

- Priming: All surfaces were then primed with USI Flexible Broadcast Primer to ensure a strong bond for the subsequent layers.

- Sealing and Finishing: Finally, a coat of USI Polyaspartic Sealer in White was applied. This not only provides a fresh and clean appearance but also a hardwearing and hygienic surface. Light aggregate, specifically 46 (5gallon) USI White Aluminum Oxide, was broadcast throughout the floor area to enhance slip resistance, an essential feature for safety in wet environments.

PRODUCTS USED

888.110 USI Epoxy Mortar Patch Kit

888.139.2 USI Flexible Broadcast Primer

888.449 USI Polyaspartic Sealer

46 (5gallon) USI White Aluminum Oxide