Indumar Leak Repair Solutions

Stop It Pipe Repair System

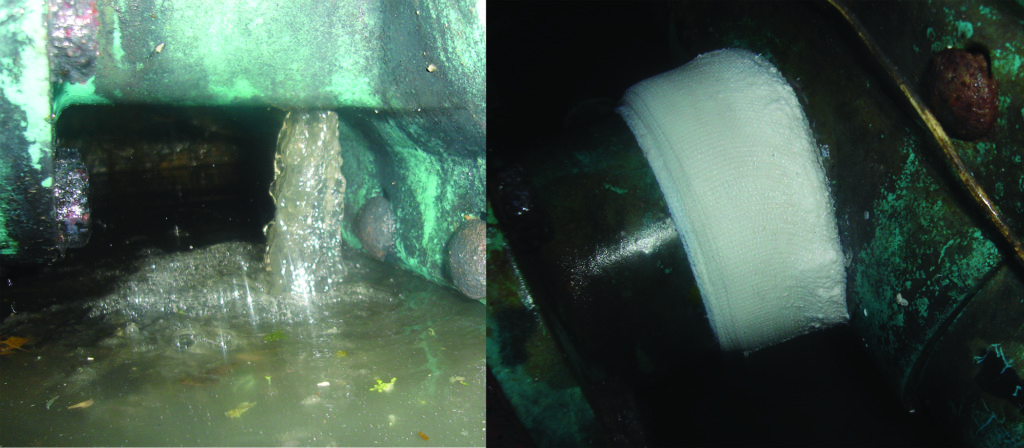

The Stop It Pipe Repair System fixes cracks and leaks in carbon steel, stainless, aluminum, copper, galvanized, PVC, CPVC, PVDF, polyethylene, polypropylene, fiberglass and other pipes so you don’t have to face the consequences of a shutdown until the pipe is replaced.

Stop It can be used almost anywhere – including underwater and in chemical and military facilities – to repair chemical, steam, process and water lines. It’s an in-field repair system that can be quickly applied by one man, leaving other maintenance staff free to deal with other concerns.

The Stop It Pipe Repair System consists of a knitted, fiberglass tape coated with special urethane resins that are water-activated to change from a wet adhesive tape to a hard urethane plastic in 30 minutes. No tools and no hot work needed to get your plant back to full capacity as quickly as 15-30 minutes.

Each kit includes a plug of Fix Stix epoxy to plug leaks or cracks or to provide a smooth transition at offsets. Bonds through adhesion and the mechanical bond resulting from the tension of the wrap. While Stop It can be used on straight runs of pipe, its conformability makes it especially useful for repairing leaks at bends, crosses, tees, or any other location.

Stop It HP

When high-pressure pipes leak, the seepage can affect the environment, production and your company’s bottom line. Fixing it quickly and securely is a must – and reinforcing the pipe walls so that it never gets to that point can save the facility significant time and money later.

With Stop It HP epoxy leak sealant, you can repair pipeline cracks and leaks and reinforce diminished pipe walls in minutes so that they can handle working pressures up to 2,000 psi. In as little as four hours, operations can be resumed, and Stop It HP exhibits maximum pressure performance after 24 hours of curing.

It’s the durable solution that’s trusted to repair a damaged methane gas line in the inhospitable Dakar, Africa desert. After the fiberglass pipeline was damaged by a motorized grader, Fortesa International used Stop It HP to cover 11 feet of the tube, sealing the five-foot hole and the non-visible damage from fracturing.

Surface preparation consists of removing any loose scale and lubricants or greases. The system should be relieved of all pressure until the product is fully applied and cured. Application surfaces should be dried prior to application and warmed if the pipe surface is less than 50°F or cooled if greater than 100°F. Application entails mixing a pre-measured two-part sealant, wetting a fibrous reinforcement tape, and wrapping the tape onto the pipe surface. Applications can be made regardless of pipe orientation.

Sealant mixing takes seconds and can be immediately applied to the reinforcement tape. The wetted tape possesses a working time of approximately 8-10 minutes. The exact application time will depend on the specific conditions under which Stop It HP is being applied.

Stop It Fast Patch

Stop It Flat Patch is a leak sealant product designed for applications where localized repair is needed or full pipe wraps are impractical. The carbon fiber composite repair system quickly restores operations for storage tanks, floating lids, vessels and large-diameter pipes operating at pressures up to 1,000 psi, and provides localized corrosion inhibition.

Stop It Flat Patch surface preparation consists of removing any loose scale and lubricants or greases. The surface should be relieved of all pressure until the product is fully applied and cured. Application surfaces should be dried prior to application and warmed if the pipe surface is less than 50°F or cooled if greater than 100°F.

Application entails mixing a pre-measured two-part sealant, wetting felt and fibrous reinforcement tape, and applying the fabrics onto the surface. Applications can be made regardless of surface orientation and result in a durable coating with superior pressure-sealing capabilities.

Sealant mixing takes seconds and can be immediately applied to the reinforcement tape. The wetted tape possesses a working time of approximately 8-10 minutes. The exact application time will depend on the specific conditions under which Stop It FP is being applied.

Leak & Spill Kits

First Response Leak Repair Kit has Everything in one box for maintenance and safety teams to quickly respond to most common leaks, cracks, and gashes in pipes, drums and tanks. Each kit includes a small, medium and large size of the Stop It Pipe Repair System, five Fix Stix epoxy, 18 assorted wooden plugs, rubber hammer, two Plug-N-Dike Plug Rugs, three Plug Patties, lead wool filler pack, hot/cold hose repair tape.

Emergency leak control kit D is great for hazardous-material leaks in any type of low-pressure vessel, universal kits contain everything needed to patch cracks, gashes and holes of all shapes in tanks and drums. All bolts, back-up plates, and hardware are manufactured from 304 stainless steel.

Kit AE contains all the items listed for kit “D,” plus items for larger holes, cracks and gashes. These include one 8” x 12” stainless steel plate lined with ¾”-thick soft neoprene material and three T-bolts with preassembled wingnut washer combos. A second 8” x 12” stainless-steel neoprene-backed plate is included with hardwood cribbing ladder patch and two 22’ heavy-duty nylon straps.

Our pipe leak control kits are Designed to quickly respond to leaks in straight runs of piping. Simply snap the clamp around the pipe, drop bolt head through open-slotted lug, and tighten nuts. Versatile clamps respond to water, wastewater, fuel, chemical, air and gas leaks.

Repair clamps are made of corrosion-resistant 304 stainless steel, lugs are made of rugged-ductile iron and shop coated for added protection. Bolts are plated for longer life. A choice of gasket material offers superior resistance to oils, aromatic and aliphatic hydrocarbons, condensates, gasoline and natural gas.

All External Pipe Leak Control Kits include extra-solid neoprene and closed-cell foam gasket material for odd-sized, out-of-round, and corroded pipe applications. Accompanying tools are available in standard or non-sparking versions. Kits are packaged in a heavy-duty carrying case.

Kit C-3 contains three large clamps for 5”, 6” and 8” diameter pipe, extra gasket material and installation tools. Clamp sizes are 5”, 6” and 8

Pipe plugger kit C-1 can Quickly plugs open-ended pipes, allowing you to instantly plug knocked-off pipes carrying water, fuel, chemicals and gas. Great for knocked-off gas meters and tank truck discharge valves.

1” to 5” sizes have pressure-relief vents to help get the plugs seated under pressure. Pressure relief vents on 1 1/2” through 5” plugs can connect to enclosed valve and discharge hose. This enables fluid or gas to be rerouted to another line, discharged to a recovery vessel or flared. The Pipe Plugger Kit can also be used for drain line cleaning and nitrogen purging operations.

Kit C-1 contains 10 stainless steel pipe plugs, valve and discharge hose set, all necessary tools for installation and heavy-duty carrying case.

Roll-over Kit F covers a large hole, crack, or gash in a large vessel or tank with a patch that conforms to the curvature of the vessel. The patch uses a variety of T-bolts to support itself directly to the hole. The leak is then sealed by tightening the compression bolts around the frame, conforming the patch to the vessel.

Kit F contains one stainless-steel patch measuring 13” x 23” with 3/4” neoprene gasket. One stainless-steel support frame with compression bolts, three stainless-steel T-bolts with preassembled wingnut washer combos, all necessary tools and heavy-duty carrying case.