400 Series – Resimac Rubber Repair

400 Series – Resimac Rubber Repair with Nick Cliff

Rubber Repair Materials – 400 Series Attributes

- Impact & wear resistance

- Paste Grade & Fluid Grade

- Internal applications (ie. Pumps, vessels)

- Excellent chemical protection

- Application on metal surfaces underwater

- solvent-free (No harmful smells)

- Applied with plastic spatula, applicator or brush

- Can be applied on metal substrates

401 GP 60 Putty – Elastomeric Repair Paste

- fast-curing and hard wearing

- 4-5 minute pot life

- 3-4 hours hard dry

- Ideal for repairs to conveyor belts and gaskets

- Supplied in easy-to-use cartridges

The product is packed in 3:1 mixing ratio cartridge with mixing nozzles. The dispensing gun has been designed to fit the 401 GP 60 putty (400ml) cartridge

HOW TO USE:

- To dispense 401 GP 60 Putty mixed from the cartridge, preheat the cartridge to 25-30°C, place the cartridge in the gun. Pump the trigger. Mixed product will be dispensed onto the repair surface.

- If the cartridge cannot be preheated, do not use the mixing nozzle. Use the gun to dispense the product. Dispense onto clean mixing surface.

- Mix the 2 components together using a spatula

- Use an applicator tool to apply the mixed product to the repair surface.

- 401 GP 60 putty is ideal for Conveyor Belt Repairs

- Abrade the rubber surface with a MBX bristle blaster or mechanical grinder

- Prime the prepared rubber surface with 402 Multi-Surface Primer

- Mask out the repair area

- Cut some reinforcement tape to cover the repair/hole

- Apply mixed 401 GP 60 putty onto the repair surface and embed the reinforcement tape

- Once the reinforcement tape is in place, apply on encapsulating layer of 401 GP 60 putty

- Peel away the masking tape

- Lay a plastic sheet over the uncured resin and smooth out any imperfections

- Once the 401 GP 60 putty as cured, peel off the plastic sheet

- Resiflex 401 GP 60 Putty – Fast curling, rubber repair paste. Supplied in 400ml cartridges. Simple and easy to use. Ideal for repairs to conveyor belts and gaskets

406 GP 85 Repair Putty

- Two component, solvent-free urethane elastomer

- High build capability – 1″ without slump

- Shore A Hardness of 85

- 900% Elongation (BS EN ISO 37)

- Very abrasion resistant

- Heat Resistant

- Up to 122°F (Full Immersion)

- Up to 176°F (intermittent Contact)

- Up to 248°F (Dry Heat)

IDEAL USE:

- Conveyor Belt Repairs

- Gasket Sealing

- Rubber lining of Process Equipment (Chutes, Hoppers, Fans, Pumps)

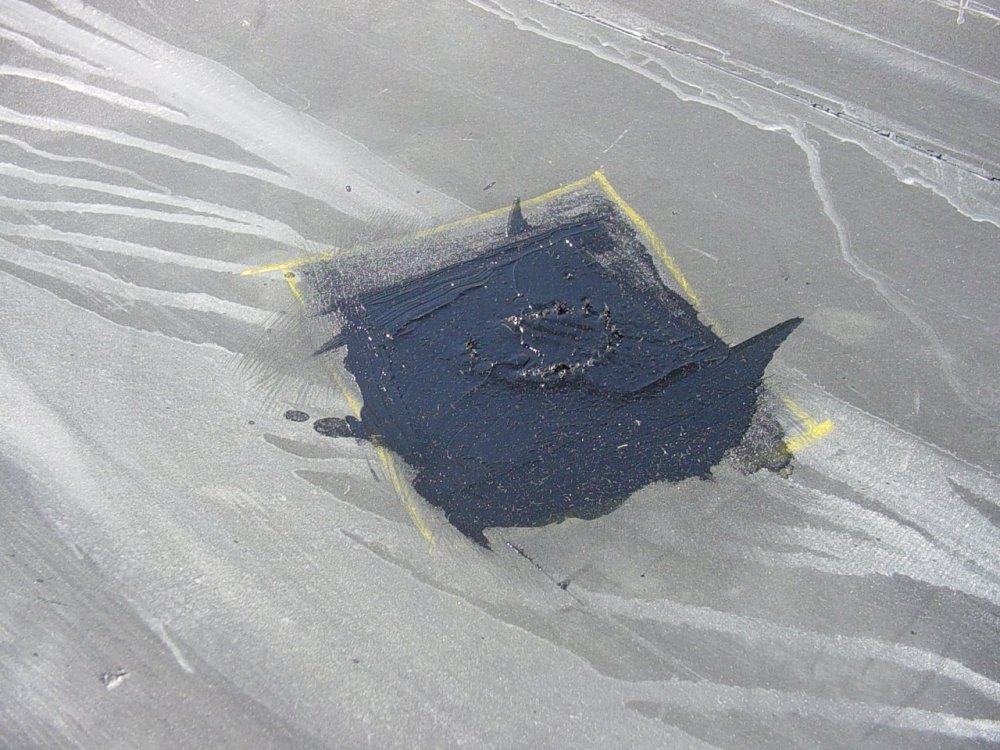

Mining Conveyor Repair:

- Surface prepared using handheld mechanical grinder

- 402 Primer, 401 GP 60 with RES 808 Reinforcement Tape

- Belt returned to service in 2 hours

Sugar Refinery Conveyor Repair:

- Surface prepared using handheld MBX Bristle Blaster grinder

- 402 Primer, 401 GP 60 with RES 808 Reinforcement Tape

- Belt return to service the same day

Reforming Damaged Gaskets:

- Surface prepared using handheld mechanical grinder

- Surface conditioned with solvent based adhesion promoter (Resiflex 402)

- Resiflex 401 GP Rubber Repair Paste applied to mating surfaces

Butterfly Valve Repair:

- Surface prepared using handheld MBX Bristle Blaster grinder

- Applied 904 Release Agent on mating gate valve surface

- 402 Primer and then 401 GP 60 Putty applied to inner rim @ 4mm

*These products can also be used on Expansion joints on highway

Resimac Resiflex 401 GP 60 Putty (Package of 10 500gm Sachets)

Resimac Resiflex 401 GP 60 Putty is a two component fast curing solvent free urethane elastomer. The product has been specifically developed for repairs to a wide range of rubber surfaces such as Nitrile, Neoprene & Natural rubber.

Resimac rubber repair materials are based on the latest elastomeric urethane technology. They have been developed to give fast and effective solutions for repairs to rubber and metallic surfaces.

Resimac Resiflex 402 Multi-Surface Primer

Resimac Resiflex 402 Multi-Surface Primer is a single component solvent based primer for use with Resiflex 401 GP 60 Putty. The primer has been developed to ensure excellent adhesion between 401 GP 60 putty and any rubber or metallic repair surfaceResimac High Strength Reinforcement Mesh Tape 808 – 3″ x 13′

High Strength Reinforcement Mesh Tape 808: Durable Polyester Mesh for Enhanced Metal Repair The Resimec Tape 808 is a robust polyester mesh specifically engineered to complement Resimac metal repair systems, adding an extra layer of strength and durability to the pipe wrapping process. This mesh tape is an essential component for reinforcing repairs, ensuring long-lasting and resilient results. Optimized for Use with Resimac Repair Systems:- Designed to integrate seamlessly with a range of Resimac products, including 101 Metal Repair Paste, 104 Metal Repair Fluid XF, 106 Metal Repair Paste XF, and 302 Epoxy Repair Cement. This compatibility ensures that the High Strength Reinforcement Mesh Tape 808 enhances the effectiveness of these metal repair solutions.