Peerless Synthetic Rubber

By: Stormy Shaw

Synthetic rubber has properties like natural rubber, but with greater resistance to abrasion, wear and water. Additional advantages over natural rubber include; low cost alternative material to natural rubber, longer lasting aging properties and it hardens with time, rather than softening.

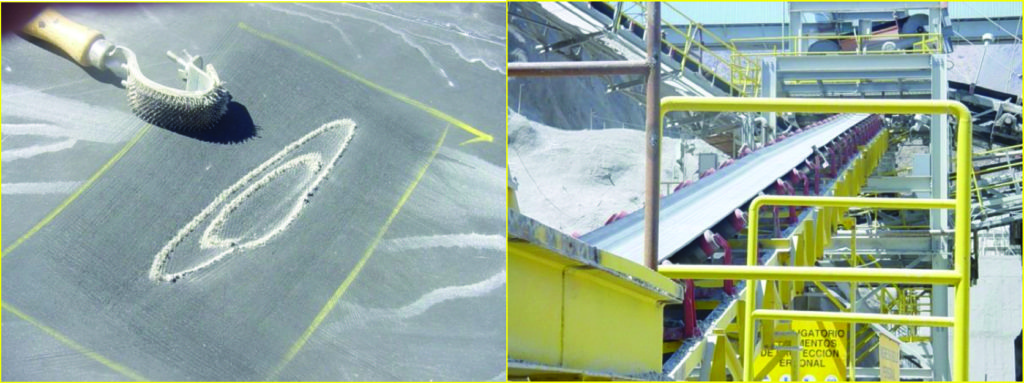

Synthetic Rubber Putty Ultra

Peerless Synthetic Rubber Putty Ultra is a free-flowing liquid polyurethane that becomes a smooth trowel-able paste. It cures to a tough, flexible rubber compound that is resistant to wear and abrasion. Some typical uses include agitator blades, chutes, damaged rubber, fans, pulleys, rollers, vessels, conveyor, belting, ducting, linings, pumps, screens and valves.

After priming, apply a very thin scratch or smear coat directly to the prepared surface to maximize surface contact before proceeding to apply additional product to the desired build. Ensure product has been worked into all cracks and voids to eliminate air bubbles. If applying several coats or layers, any previously applied product must be roughened if it has been left to cure for more than 24 hours.

In some cases, a softer, more resilient product may be desired. SR flexibilizer may be added to reduce hardness of the product. This can simply just be mixed into part A of the synthetic Rubber Putty Ultra during preparation.

Variations in cure time may arise due to the amount of material being, the thickness of material, the surface temperature and the product temperature. The cure time may be increased by applying external heat to the prepared surface before application of the product. This can be done with heat lamps or other heat sources. The cure time can be reduced by cooling the product before mixing.

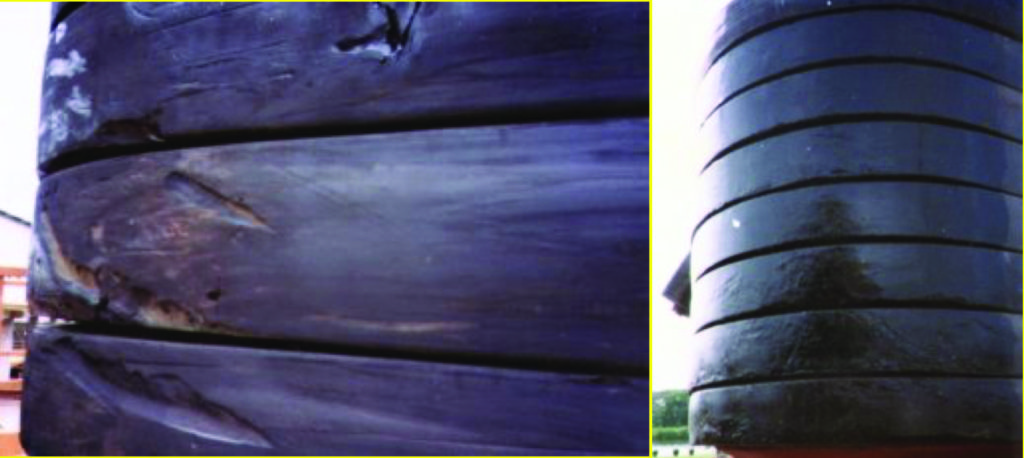

Synthetic Rubber KIS Bandage Wrap

This resistant, fabric reinforced liquid elastomer compound has a high stretch to follow contours on applications. It cures to a tough flexible rubber composite that moves and stretches as needed. Typical applications to use the KIS bandage wrap on are pipes, ducting, flanges, expansion joints, drainage and elbows.

After priming, apply the mixed binder directly to the fabric, unrolling some of the bandage as the fabric is being wet. Roll the bandage up as more application takes place. Begin by placing the wet bandage onto the surface and slowly unwinding. When applying several coats, any previously applied product must be roughened if it has been left for more than 24 hours. This alloy epoxy/polyurethane polymer system is free of all solvents, has outstanding resistance to shock and stress, is suitable in new linings or repairs.

KIS Bandage Wrap is easy to apply and has high elongation which proves it is priceless in unstable foundation environments. It has excellent capability for joint and crack remediation in concrete slab walls. KIS is versatile in applications and will follow any contour encountered. It has variable widths and lengths to suit most needs. KIS is tested and compliant for potable water.

Benefits of KIS Bandage Wrap are that it is light weight, which means it has a low transport cost, it is simple to install, has a long lifespan, is versatile and has simple construction. The basis of the resin based technology initially centered on the use of epoxy resins to fulfill demanding industry requirements. This can be utilized in mining, water, power, pipeline, mineral processing, oil refining, material handling and storage industries. It is perfect for using for boot seals, joint sealing, crack bridging and pipe wrapping.