Eliminating the Guesswork: Mastering Casing End Seals with Denso-Viscotaq

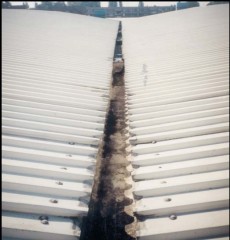

In the field, real-world conditions rarely match engineering drawings. Casing end seals are no exception. Pipes shift, measurements mislead, and unexpected gaps appear—especially under highways, railroads, or aging roadbeds where…

Read more