This BLOG will cover TIPS to prevent coating failure as well as Helpful Hints to prevent a Repair Kit Coating from failing.

3 TIPS TO PREVENT COATING FAILURE

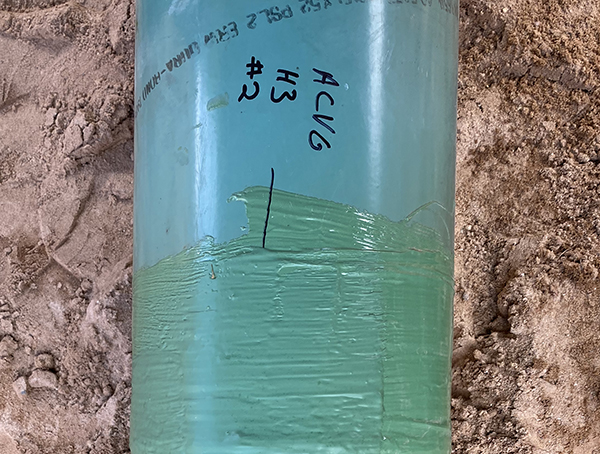

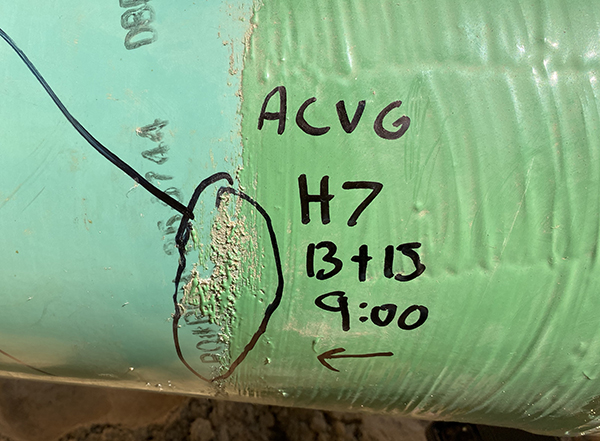

#1 Document Everything!!! (If you did not document it, you do not do it.)

#2 Manufacturers Application Specification MUST BE followed. (Make sure the Safety Data Sheet is on site)

#3 Record the conditions

– surface temperature of the pipe

– atmospheric temperature

– dewpoint (record the dewpoint along with pipe surface temperature to ensure that the surface temperature is a minimum of 5°F above the dewpoint and a minimum of 50°F, through cure per manufacturers specifications)

– relative humidity

-batch numbers A & B with expiration dates

-check the shore D hardness to see if it matches the manufacturer specification before back filling

*If you do not record these facts and there is an issue, it is difficult to determine what part of the process created the failure.

HELPFUL HINTS TO PREVENT A REPAIR KIT (50ml cartridge) COATING FROM FAILING:

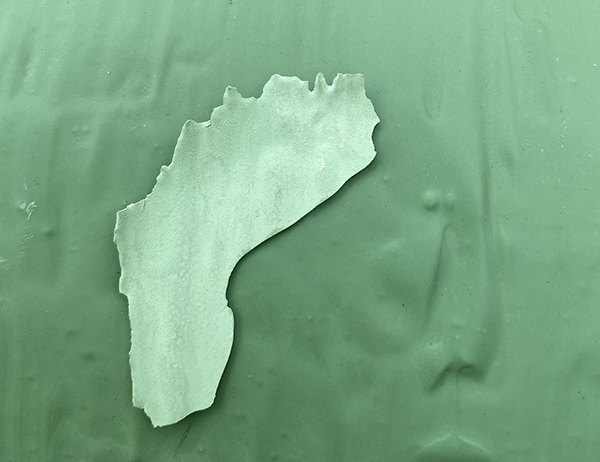

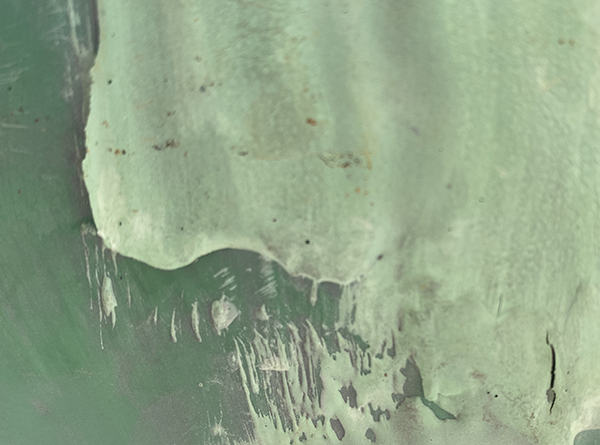

- Incomplete surface preparation

- use sand paper that is 80 grit or brush blast the holiday one inch all the way around it

- keep sand and dirt away from coatings when it is windy out

- do not coat when it is raining out unless you can tent the area until the coating can cure

- Improper pipe temperature vs dewpoint

- Coating not thoroughly mixed, needs homogenous color

- Pipe buried prior to coating achieving required hardness/cure

Do you have more questions or need more tips?

Contact USI at 248.735.7000 or office@USIgroups.com