We have all had the occasion to pull the first couple of joints out on an HDD and the coating is extremely damaged.

THE DRILL:

#1 Look at the alignment of the pipe in the drill hole. Is there a sharp turn in the drill? If there is, the pipe may be dragging on an abrasive ledge.

#2 Is the drill of adequate diameter for the substrate conditions?

#3 Was the drill cleaned and swabbed well before the pull?

#4 Was there enough high viscosity mud pumped in to fully lubricate the pipe? There is nothing worse than a dusty pull.

THE COATING:

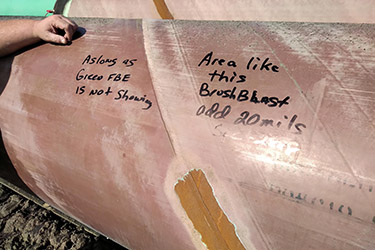

#1 Was the ARO applied uniformly per coating manufacturers specifications?

#2 Are there any high asperity areas on the pipe? Spiral Weld pipe is always subject to some damage on the welds.

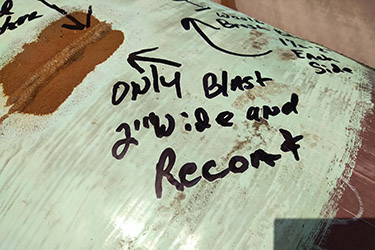

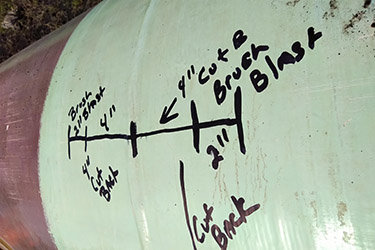

#3 Was the girth-weld coating applied to the correct mils across the weld area?

#4 Does the girth-weld coating transition smoothly from parent coating over the cap weld, with no catch points?

#5 Are the button welds and cap welds even and not too high?

Have more questions about HDD and Coatings? Contact a USI Technical Consultant Today 248.735.7000 or office@officeusigroups-com