Pipe and Pipeline Color Code Standards Explained

Working in the vicinity of pipes or directly on pipelines can be dangerous. For the safety of all involved, safety and regulatory organizations have designated color code standards for pipes and pipelines. It is important to follow gas pipe painting codes. A few of these organizations include:

- American Public Works Administration (APWA, USA)

- American National Standards Institute (ANSI, USA)

- Occupational Safety and Health Administration (OSHA, USA)

- British Standards Institution (BSI, UK)

The colors used in the coding systems promote consistency, clarity, and safety across industries by providing a standardized method for pipeline identification.

Pipe color code standards use specific colors to identify the substance(s) contained within the pipeline and the related safety hazards. A pipeline color code chart serves as a reference tool for personnel working with pipelines, helping them identify and understand the nature of the pipelines they encounter.

There are numerous competing standards; however, for the discussion covered in this article, we will primarily focus on the APWA standard for buried utilities (The American Public Works Association (APWA) Uniform Color Code).

Importance of Pipe Color Coding

Color coding pipelines serve two important purposes:

- Identification: Pipeline color coding provides a visual means to identify and distinguish different types of pipelines, their content, or their purpose. By using distinct colors, personnel can quickly and easily recognize the type of pipeline they are dealing with, reducing the chances of confusion or mistakes.

- Safety: Color coding enhances safety by conveying crucial information about the nature of the pipeline. It helps personnel and emergency responders identify potential hazards and take appropriate precautions. For example, color coding can indicate the presence of flammable, toxic, or corrosive substances, alerting individuals to handle those pipelines carefully and follow the necessary safety precautions.

Pipeline Color Code Charts

Pipeline color code charts are often based on recognized standards or guidelines, such as the APWA, ANSI/ASME A13.1, and BS 1710 standards, these gas pipe painting codes are important. These charts are also known as pipeline color code standards or reference charts. The charts serve as a visual guide that provides information on the recommended colors for identifying different pipeline types based on their contents, purpose, or hazards. Additionally, text or symbols are included to indicate the meaning or significance of each color.

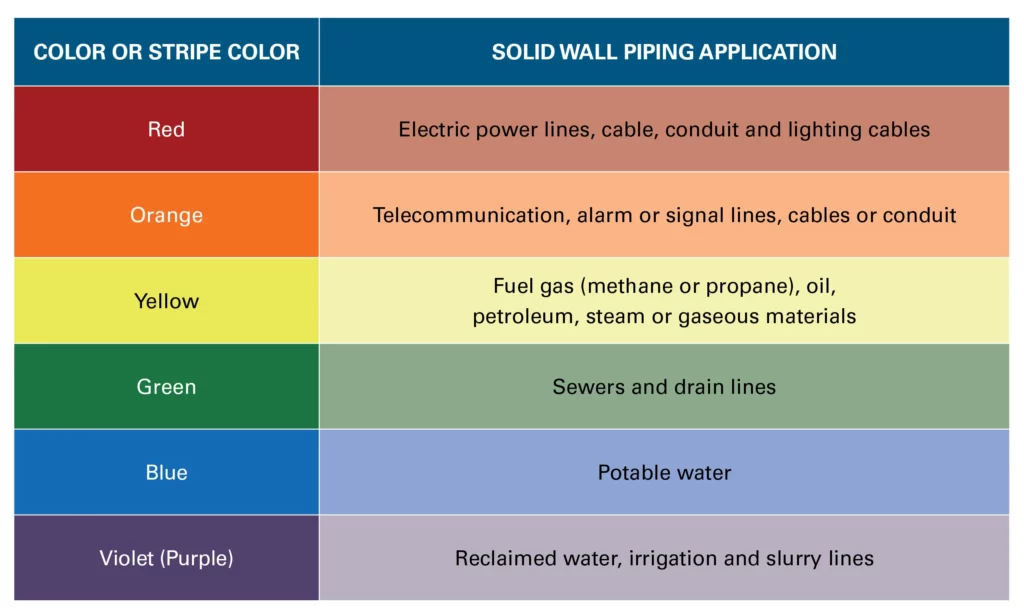

APWA Color Chart (American Public Works Association)

The APWA Uniform Color Code is considered a universal marking guideline across the United States and is the most recognized by professional underground utility locating companies. This Color Code system provides a universal understanding of underground utilities’ marking for construction and engineering projects. It suggests the following color scheme:

- Red denotes high and low-voltage electricity.

- Yellow designates natural gas, steam, propane, and other fuel or heating products such as fuel oil.

- Orange illustrates telephone, fiber optics, cable TV, satellite, and other communication lines.

- Blue marks out potable (drinkable) water sources such as city, municipal, and domestic.

- Green designates storm and sanitary sewer pipes, both gravity and force.

- Purple signifies non-potable (non-drinkable) water sources such as grey water, pond water, irrigation, and slurry lines.

- Pink is generally used for temporary survey markings. In some instances, Pink is used to designate unknown utilities.

- White is used by excavation companies performing work to mark out the area to be surveyed.

Maintenance and Operations

Color coding facilitates maintenance activities by aiding in the identification of specific pipelines and following gas pipe painting codes. It helps maintenance personnel locate, inspect, repair, or replace pipelines more efficiently.

- Additionally, color coding can assist in operational processes, such as identifying the correct pipelines for product transfer or monitoring flow direction.

- Regulatory Compliance: Color coding pipelines can align with industry standards or regulatory requirements. Following color code standards ensures compliance with guidelines or regulations set by organizations or authorities, promoting consistency and safety across the industry.

Maintaining a pipe color coding standard is an important safety measure. The color code system assists in preventing accidents by ensuring that workers can quickly and easily identify the contents and function of pipes in a piping system. By following the pipe color coding standard, workers can avoid potentially dangerous situations, such as accidentally connecting lines carrying different fluids or gases.

Proper Pipe Marking & Labeling

Labeling pipes in an industrial facility or field setting can seem daunting, but with the proper information, the task is simple. Pipe marking is crucial to staying ANSI, OSHA, and BSI compliant, so it’s essential to get it right!

Applying and maintaining pipe markings and labels are critical to staying compliant; it’s advisable to consult your region’s applicable standards or regulations to ensure compliance with the correct pipeline color coding requirements.

To conclude, specific industries or regions may have variations or additional codes beyond the standard guidelines. However, by following a pipe color coding system, workers can avoid potentially dangerous situations, such as accidentally connecting pipes carrying different fluids or gases. This visual communication method promotes safety, efficiency, and compliance within various industries that deal with pipeline systems.

Denso Viscotaq EZ Wrap

Paintable tape that provides immediate adhesion, is a-polar, rejects water, and requires no cure time.

This product contains a “Paintable topcoat backing“

An amorphous, apolar, semi-solid, polyolefin coating with a paintable topcoat backing for exceptional corrosion prevention and waterproofing for a variety of substrates.

TYPICAL APPLICATIONS:

- Waterproofing of gravity-fed pipes, manholes, seams, penetrations, and cracks

- CUI applications

- End seal for pipe casing

- Tank chimes

- Buried pipelines with minimal surface preparation

- Waterproofing for bell & spigot joints and more

Pipepine color safety The American Public Works Association (APWA) Uniform Color Code