Choosing a Surface Preparation Method

There are a variety of methods when it comes to surface preparation for an application. It is important that the method you choose will provide the required standard of preparation, will meet the requirements of the customer and is appropriate for the environment. The condition of the substrate prior to coating is key because most cases of coating failure are due to improper surface preparation. Be sure to do it right the first time.

Cleanliness

To ensure the success of an applied system there are two fundamental qualities to surface preparation, the first being cleanliness. The substrate must be clean for proper adhesion. Coatings are not normally very tolerant to contamination. Chemical or physical interaction is required between the coating and the substrate and can be obstructed by contaminants. These contaminants may interfere with the various standards that have been developed over the years to classify the cleanliness of prepared steel. We at USI go by the standard set by NACE International.

Detecting Surface Contamination

There are various ways to detect surface contamination on a substrate such as the use of soluble salts, like Chlor*Test. This test uses a unique patented extract solution to retrieve surface salt contamination. This special extract enhances retrieval rates, thereby increasing accuracy. Most specifications do not address sulfates or nitrates because there has never been a sulfate or nitrate field test kit. Now there is a complete test kit available that tests all three salts. CHLOR*TEST “CSN Salts” offers the specifier the availability of trouble-free performance testings, in the field, for chlorides, sulfates, and nitrates with one extraction. You can detect mill scale by spraying a fine mist of acidic copper sulfate solution on to an area of the freshly blasted steel. The steel turns a bright copper color and any mill scale present will show as black spots.

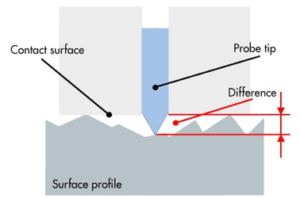

Profile

Profile is another fundamental quality required for proper surface preparation and to ensure the success of the system to be applied. A profile is the surface roughness of the substrate and it is important to gain a successful key to the surface. Profile is a physical requirement, which simply increases the area of contact between the substrate surface and the coating. A surface profile will also affect the amount of material used. As the profile of the surface increases, so will the material usage. The best way to find the acceptable standard of preparation is to review the product data sheet. Cleanliness of the substrate should be a minimum of NACE number 2 standard, which is a bright metal with no rust. An average profile should be approximately 2 mils, which can be measured by using profiling tape or a profile comparator.

Flash Rust

Freshly blasted steel can soon be spoiled by the onset of flash rusting or spot rusting. The atmospheric conditions and the steel temperature determine the time it takes for the blasted surface to spoil. We can hold the blast by controlling atmospheric conditions with use of equipment such as de-humidifiers, heaters or products such as Hold*Blast.

Hold*Blast effectively passivates the surface and is a cost-effective, environmentally safe and compatible with all coatings. It is a surface passivator which stops the formation of flash rust for long periods of time, often several days. Surface corrosion can occur when water wet surfaces react with atmospheric oxygen. Hold*Blast pevents the formation of flash rust, by chemically changing the active surface of metal to a much less reactive state. This liquid is a concentrated organic chemistry which is added to water and sprayed onto surfaces during preparation for coating. It does not leave a film or residue to interfere with coating adhesion. It removes dust as it passivates and is a cost-effective, environmentally safe and biodegradable product.

Environmental Conditions

Environmental conditions can cause the product to not be tolerant and these limitations are listed on the product data sheet. Common restrictions that prohibit the application of materials are relative humidity, air temperature, surface temperature and substrate moisture content. Tools such as a digital dew point meter, contact thermometer, surface moisture meters, protometer and capillary sheet can help make sure that these environmental conditions are just right for application. Using these tools can help ensure that proper surface preparation is maintained.

Blasting

Abrasive blasting is when blast media is fired at the surface at a high-speed. This method removes rust, dirt, coatings and provides a blast profile even on hard metals. It is important for you to consider the material being prepared and the standard of preparation required when deciding what blast media to use. Many types of blast media are available such as; chilled iron grit, copper slag, coal slag, garnet, aluminum oxide, steel shot, glass beads, plastic media, ceramic beads, quartz, sponge media, among others. There are standards for steel which may make it necessary to prepared by water jetting or mechanical wire brushing. If you are unable to blast there are manual tools that work great for smaller areas.

Manual Abrasion

There are several manual abrasive processes you can use to prepare a substrate. Some examples of this are wire brushing, sanding, angle grinders and bristle blasters. Wire brushes are a minimal preparation method that removes loose rust and dirt. Sanding removes rust and scarifies softer surfaces. Hand held machines are available such as disc abrasion machines for manual sanding. Angle grinders remove rust and coating. These grinders scarify hard metals. Bristle blasters remove corrosion and gives you an anchor profile. Bristle blasting is a NACE specified profiling process. It uses a specially designed rotary bristle tool that can give you a visual cleanliness as achieved by grit blasting.

Post Application Testing

Post application tests can be conducted by using sample plates or test panels. These destructive tests are best preformed off the application itself to avoid errors. Pinholes are small craters in the fill. They are normally created by air releasing from the surface of the film coatings. Holidays are skipped or missed areas on the substrate that have not been coated. Both holidays and pinholes represent areas where the film is not continuous. This means that external elements can still contact the substrate. A DC holiday detector and Tinker & Rasor holiday detector are both ways to test for holidays.