The Problem

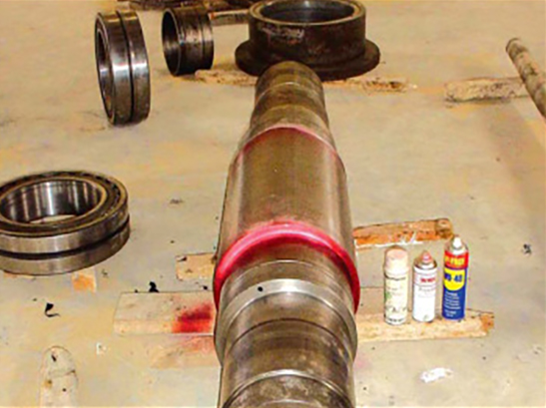

Shaft Repair: This single toggle jaw crusher is located in a mining facility. The bearings of the shaft weighing 3,000 pounds and costing over $20,000 new had been exposed as a result of this aggressive working environment and many years of use. Four areas of heavy wear were identified for refurbishment. The client required a high-performance engineering repair solution.

The Substrate

The Solution

To complete this shaft repair, the worn sections were suitably prepared to create a rough surface profile, ensuring any loose material and surface contaminants had been removed with USI Universal Cleaner. RESIMETAL 101 was then used to effect a long-lasting repair to the shaft. After a minimum cure time of 2 hours, the shaft was machined back to its original diameter and force cured at 212F for 24 hours using heating pads prior to re-installation.

RESIMETAL 101 is a two-component, engineering-grade metal repair compound that does not corrode and provides good mechanical strength in one easy application.