The Problem

The Problem

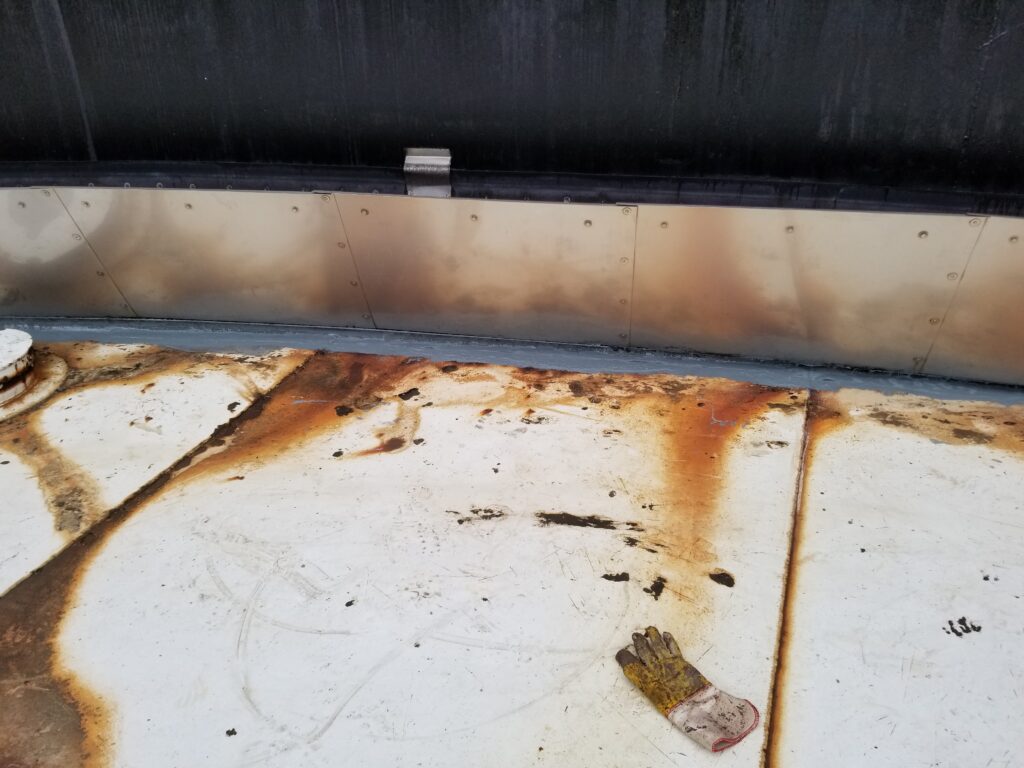

This floating roof was failing and leaking vapors into the air causing EPA issues. The customer had to decide between welding a new roof in or a make-do solutions that would need to last for two years.

The Unconventional Solutions team offered a solution that would repair the existing roof and avoid EPA fines.

The Substrate

Metal

The Solution

SOLUTION

The Unconventional Solutions team chose to use the high build solvent free RESICHEM 501 CRSG, designed for the long-term protection of steel against corrosion and chemical attack.

All the oil and grease was removed from the surface with USI Universal Cleaner. The area was then roughened with power tools, and then cleansed one more time with USI Universal Cleaner to get rid of any remaining debris.

Between the roof of the tank and the side of the tank Resimac 101 Metal Repair Paste with Resimac 808 Reinforcement Tape was used to bridge larger holes and pits.

RESICHEM 501 CRSG was used to offer corrosion resistance and then used as the glue to hold everything together. This ensures a long-lasting, protective repair.

For a complete solution and a white reflective finish, a topcoat of RESICHEM 555 Resinox was applied to provide acrylic UV protection.