The Challenge

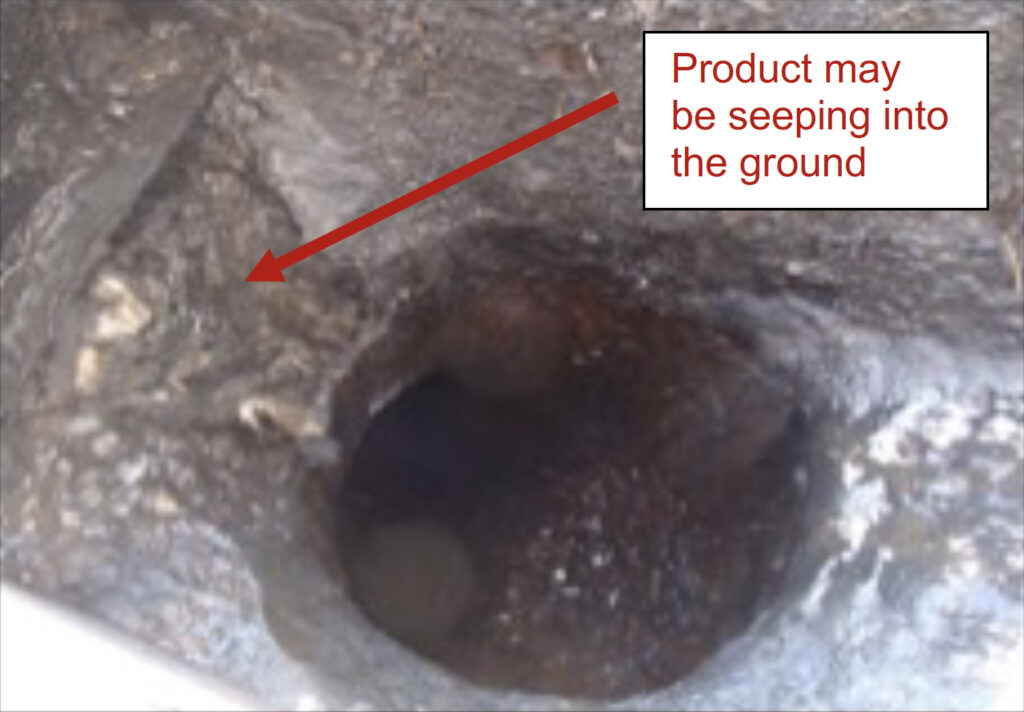

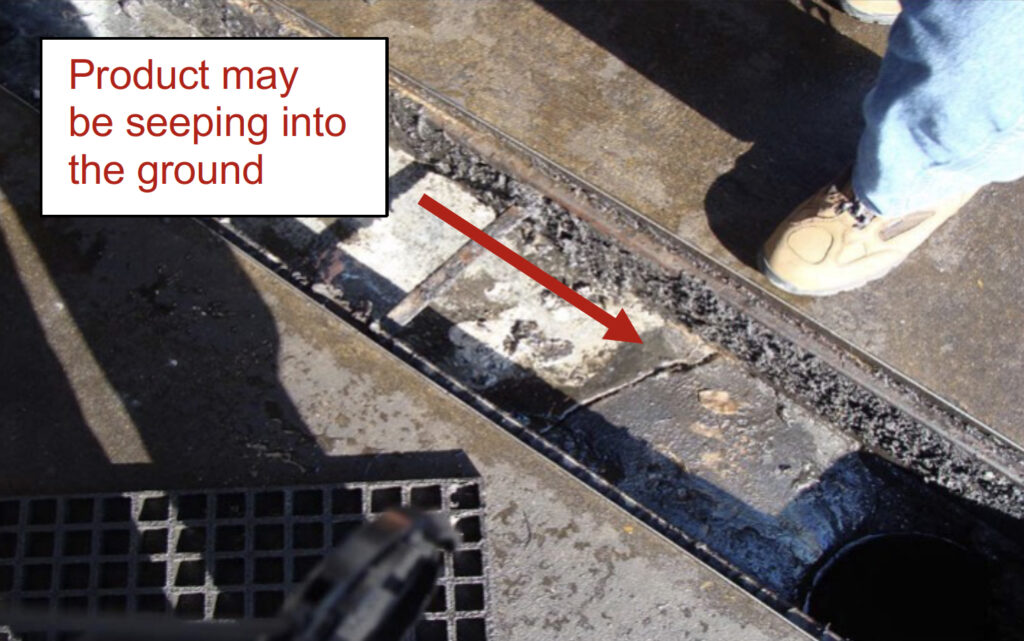

This Refinery had a concern with soil contamination by ethanol solvents and hydrocarbons. They contacted Unconventional Solutions for a system that would repair, protect, and upgrade the trench to give them a long-term solution to protect the environment without costly tear-out and re-pour of the entire trench.

The Solution

The affected area was water-blasted, dried out, and coated with Resichem Damp Seal 505. The concrete was repaired with Resichem 576 Quartz Screed, which blocked the path for leeching. After cure, Resichem 501 CRSG was applied to the area to provide a long-lasting chemical barrier.